Coco

Synopsis

The goal was to design a housewares product that improves the livelihood of an individual or group and does not harm the environment, society or the local culture.

Skills

SolidWorks | Keyshot | Proof of Concept

Credits

Professor - Arunas Oslapas

Date

September 2022

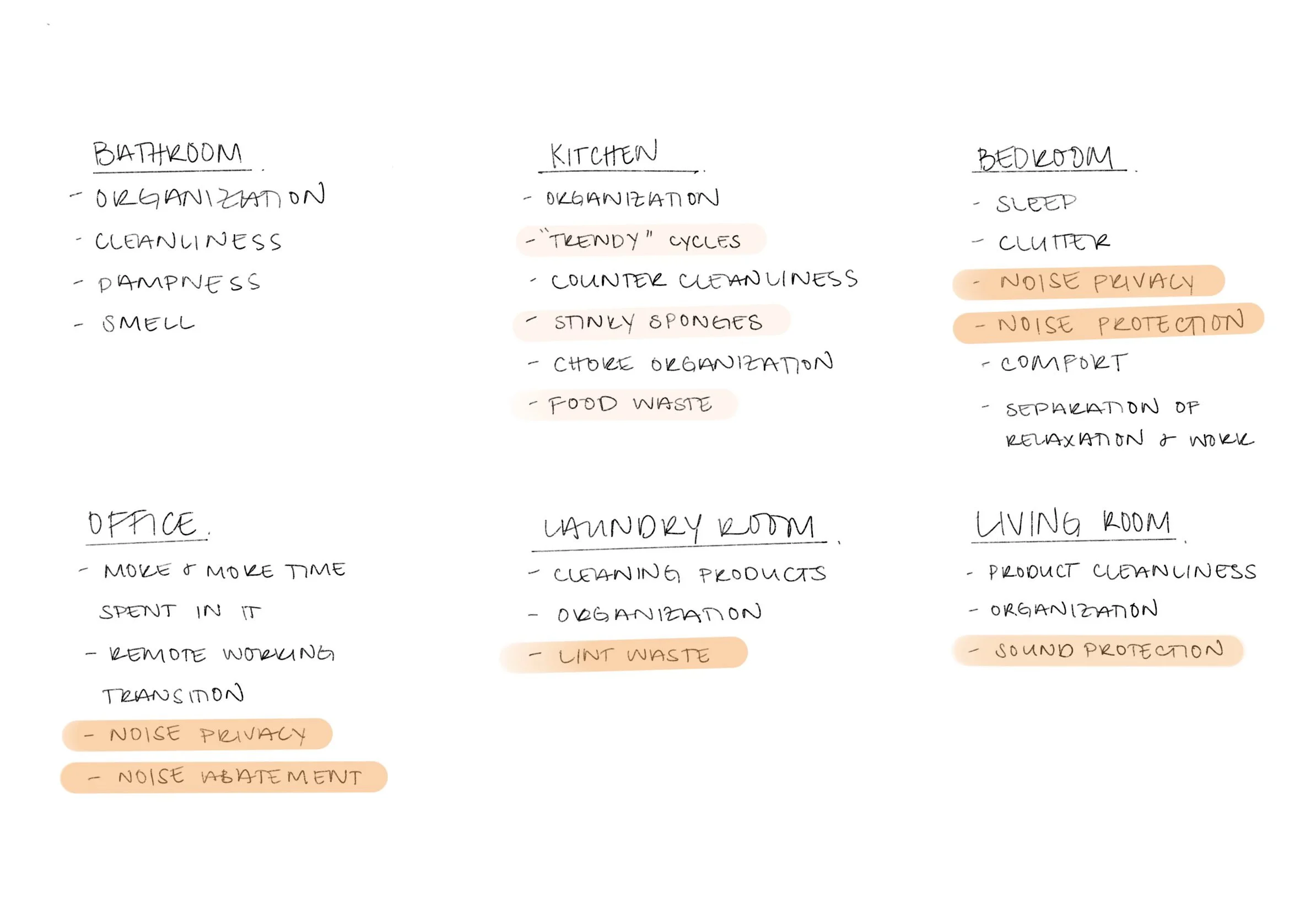

Potential Household Issues

How can we make more circular design incorporated into our everyday items?

How can lint be upcycled to become a replacement material for products that don’t use circular principles?

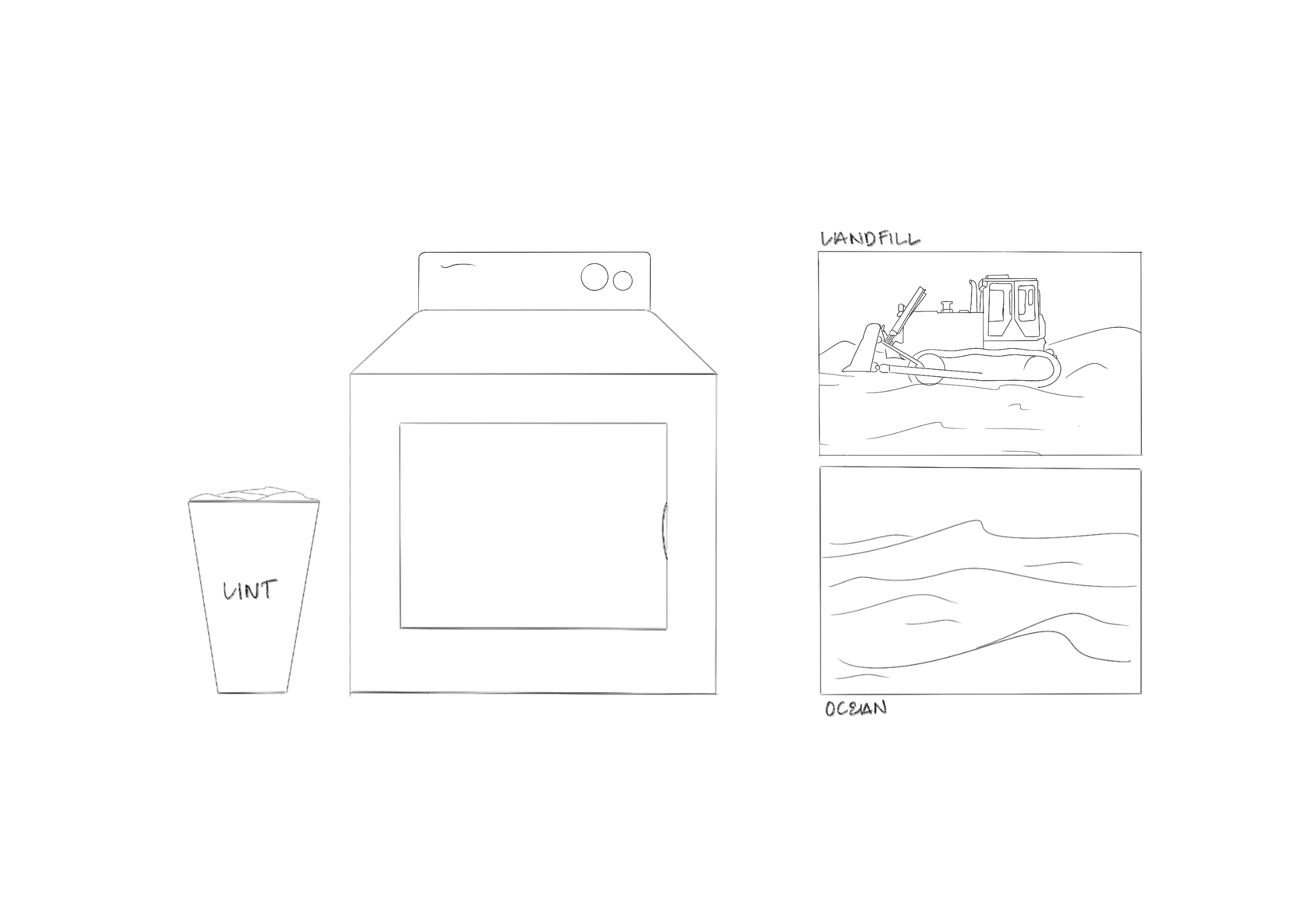

Why is lint an issue?

Lint continues to be a non-compostable and non-recyclable byproduct of commercial and domestic laundering, even while the process of doing laundry is becoming more ecofriendly.

-

Americans do 300 loads of laundry yearly, often emptying the lint trap.

Lint is filled with micro plastics.

It has no use outside of DIY projects.

-

Material properties comparable to sound panels that exist today.

Noise pollution within a person’s home intensifies a space, is a distraction and a breach of privacy.

Why is noise an issue?

The effects of sound in a domestic setting have shown more and more as we transition both school and work to a more hybrid, if not completely remote setting. As we adapt to working from our home, our home doesn’t necessarily.

-

Lack of productivity.

Poor mental and physical health.

Lacks audible privacy.

-

Intimate.

Relaxing.

Efficient and focused.

Increased privacy.

How does noise move through the home?

Sound travels through…

Poorly insulated walls

Hollow core doors

Windows

Hard ceilings and doors

Gaps below doors.

How does an acoustic panel work?

Acoustic sound panels require an absorbent material to mitigate the background noise to reduce echo in a space.

Often acoustic foam is used because sound dissipates in the porous material.

Porous materials allow sound to absorb into them, while dense enough to keep shape.

Lint in combination with wool has positive attributes as a replacement for wasteful foam found in traditional acoustic paneling because of its porous properties.

Existing Sound Panels

Could lint replace these products?

Foam

-

Good at dampening sound.

-

Expensive

Commercialized

Wasteful

Wool

-

Good at dampening sound.

-

Intensive process

Expensive

Commercialized

Other sound diffusion comes in the form of white noise, noise cancelling headphones, area rugs or solid core doors.

Alternative | Hemp | Fabric

-

Exploratory

Limiting waste

-

Little development

Expensive

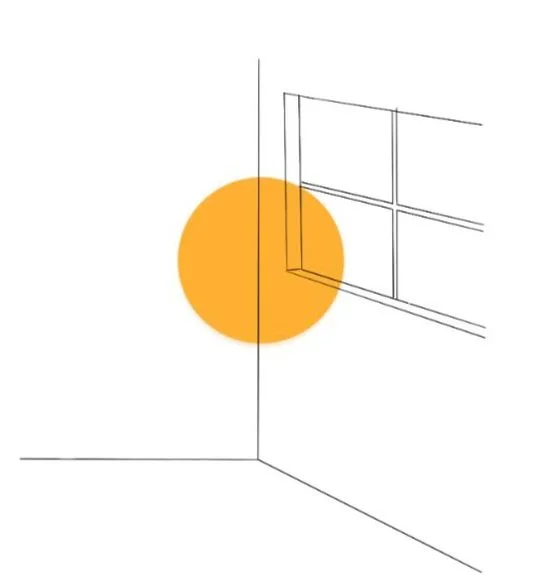

The door, and the gap below are the most prevalent areas for sound leakage, and the primary focus of this project.

How can lint be a usable material?

Wet Felting

Exploring the process of continually rubbing lint together with soap and warm water on bubble wrap to form a firm, felted material.

Needle Felting

Needle felting explored the process of using a barbed needle to combine layers of lint and wool which pulls the fibers together and binds them.

Material Exploration Conclusions

Wet Felting

Benefits

Needle Felting

Benefits

Dense, structural material.

Freedom in form, color and thickness.

Little time and energy required because it is a dry process.

Able to be manipulated with a binder to add texture.

Downfalls

Requires wool, or other secondary fiber.

Could be made with lint alone.

Able to be manipulated with a binder to add texture.

Downfalls

Non structural.

Limited variation.

Time and energy intensive.

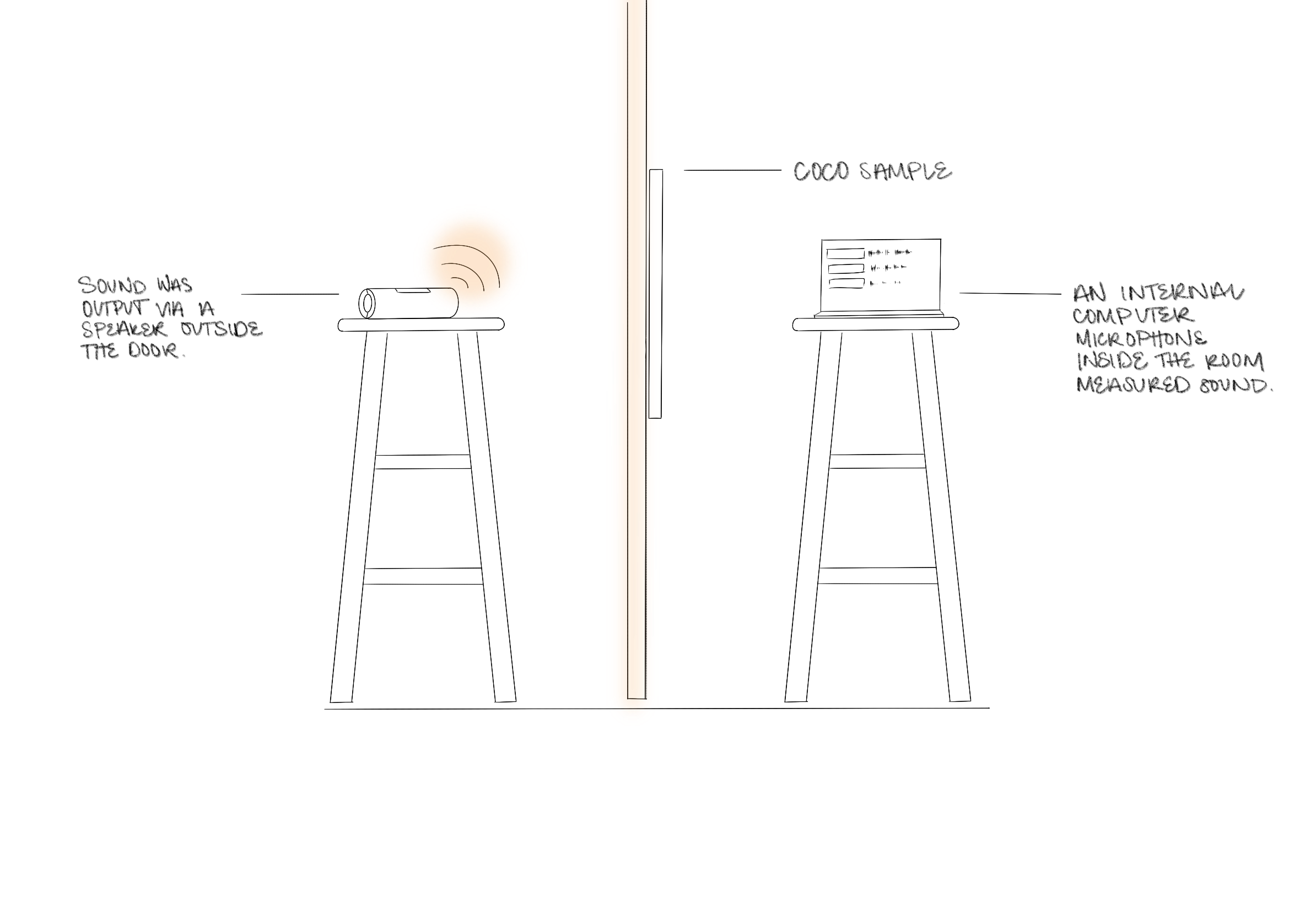

Proof of Concept

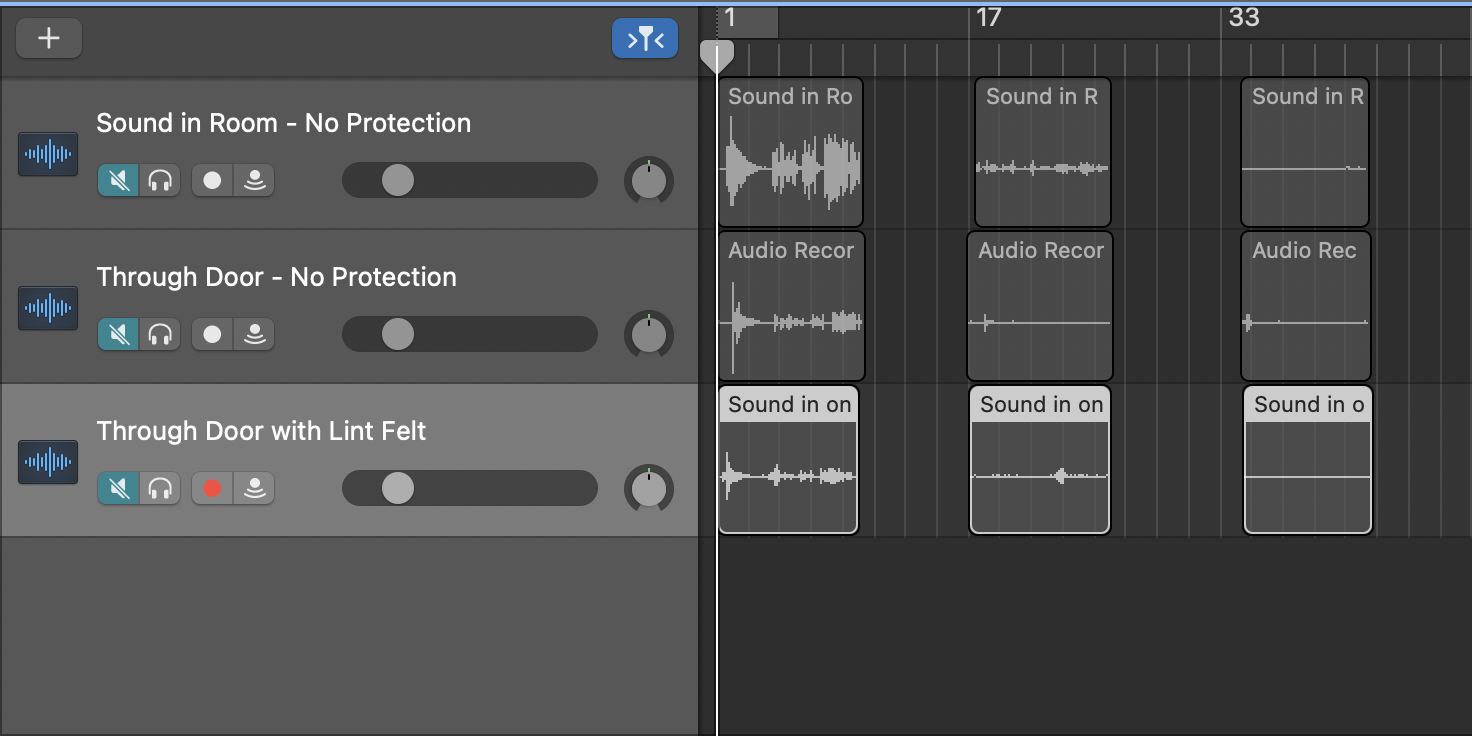

Sound testing was done by playing the same clip of audio, only changing where the sound was playing and with varying protection.

Proof of Concept

Sound Abatement Conclusions

The results conlcude that when Coco is utilized a lesser amount of sound penetrates through the door.

100% Volume

50% Volume

25% Volume

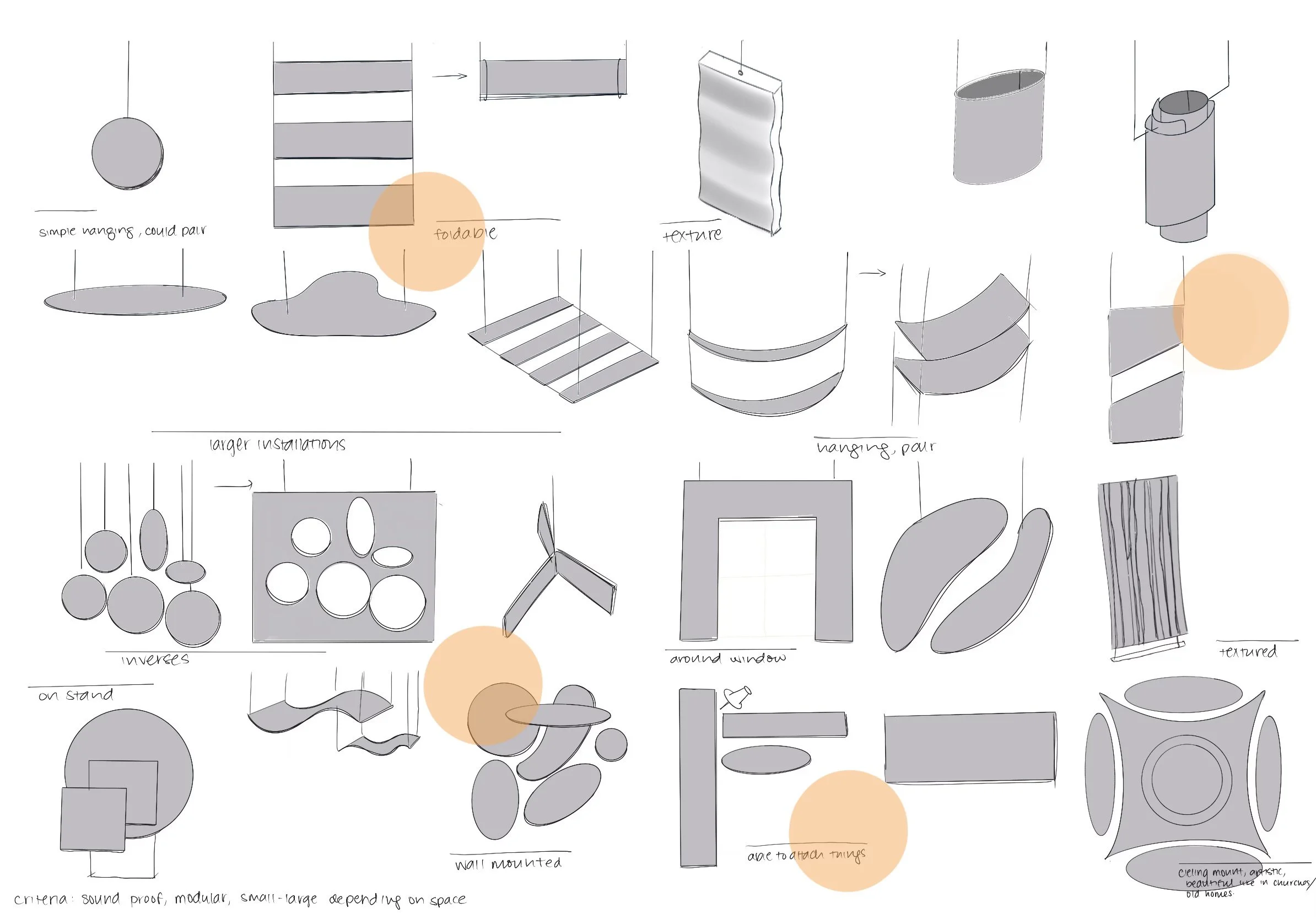

Form Ideation

If air can get through, so can sound.

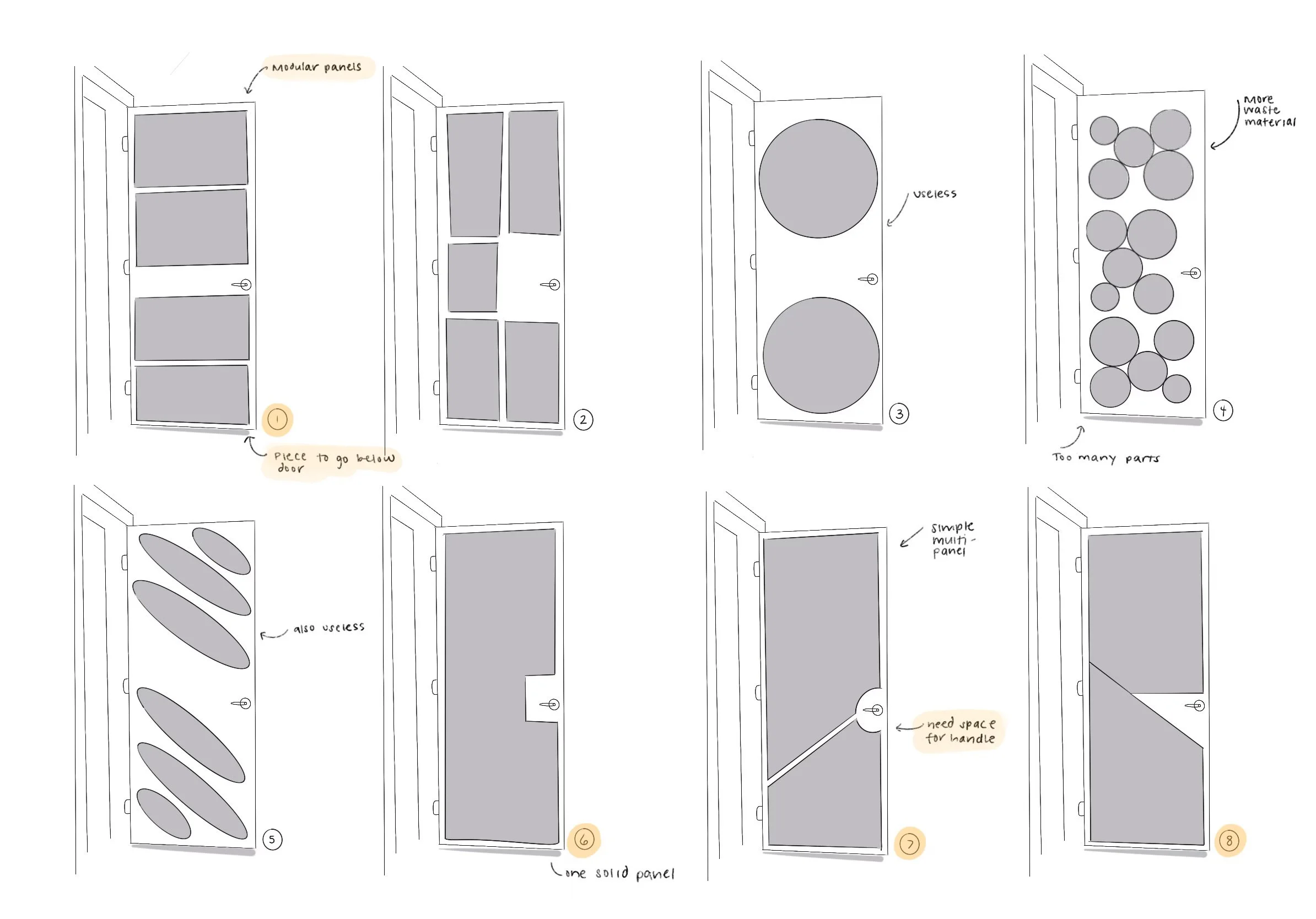

Door Ideation

Ideation of Configuration

Product Features

Coco is made up of 60% lint, and 40% wool to utilize as much lint as possible, and keep manufacturing expenses low while still being able to hold shape and form.

-

Modular elements to accommodate door sizes and other applications.

-

Due to the innate properties of lint, and its ability to have post manufacturing manipulation, each panel will have some variation in color and texture.

-

Simple, reusable fasteners allow Coco to be moved around for a flexible and modular mounting system.

Coco is for anyone who requires a distraction free, focused and private environment, which utilizes lint, a material that otherwise has no value to us.

With Coco’s modularity, the panel is able to be transferred from door to wall.

Manufacturing

Manufacturing could be done through Feltloom, a high speed industrial needle felting machine that is tolerant of nearly all materials, lint and wool being one of them.

-

Through Feltloom, it is a quick process which includes layering the fibers and fabrics and passing them through the loom. The combination comes out within seconds as one, pressed material.

-

Time and energy efficient.

There are few steps to entire manufacturing process.

Allows for variation and freedom within design.

-

Reusable fasteners that ensure modularity, while preserving the wall’s longevity.

This allows for flexibility where you place your panel, not only to preserve surfaces but for ease of use as well.

“You can close your eyes but you cannot close your ears.”

Thomas Munzel from Noise Pollution Isn’t Just Annoying - It’s Bad for Your Health